You Might Also Like

Product Groups

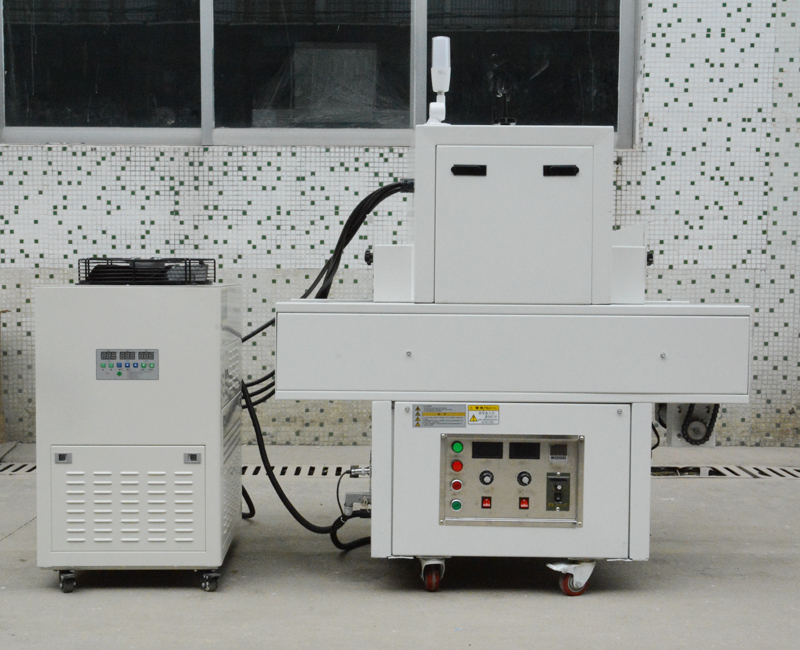

LED UV light curing machine for glue printing

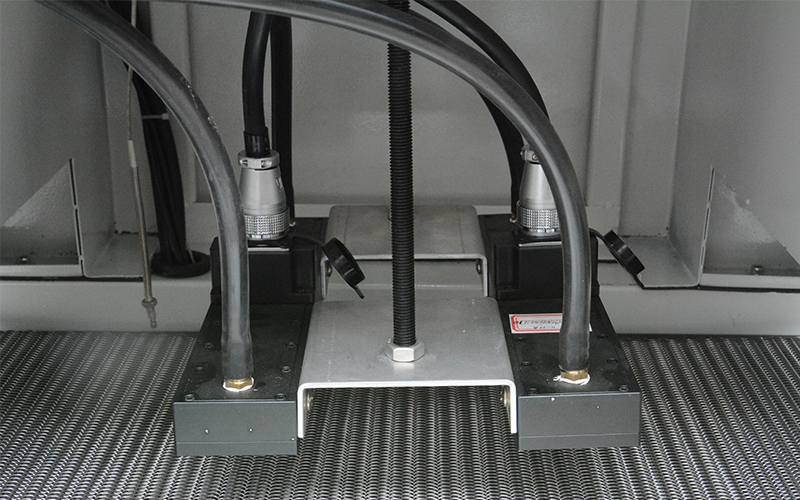

Using high-power LED chips and special optical design, the ultraviolet light achieves high-precision, high-intensity illumination; the ultraviolet light output reaches 8600mW/m2. Using the latest optical technology and manufacturing process, it achieves high-intensity output and uniformity that is more optimized than traditional mercury lamp irradiation methods. It is almost twice the illuminance of traditional mercury lamps, which makes UV adhesives cure faster and shortens. Production time has greatly improved production efficiency.

- Model:LDUVJ-2D-5.5KW

- Power:5.5KW

- Size:1200mm*650mm*1200mm

- Wavelength:365nm

- Application range:Glue bonding, silk screen printing, etc.

- Product Description

- Customer Question & Answer

Using high-power LED chips and special optical design, the ultraviolet light achieves high-precision, high-intensity illumination; the ultraviolet light output reaches 8600mW/m2. Using the latest optical technology and manufacturing process, it achieves high-intensity output and uniformity that is more optimized than traditional mercury lamp irradiation methods. It is almost twice the illuminance of traditional mercury lamps, which makes UV adhesives cure faster and shortens. Production time has greatly improved production efficiency.

COMMODITY PARAMETERS

| Product Name | LED UV light curing machine for glue printing | Product model | LDUVJ-2D-5.5KW |

| Dimensions | 1200*650*1200mm | Power requirements | Three-phase five-wire 380VAC 50Hz |

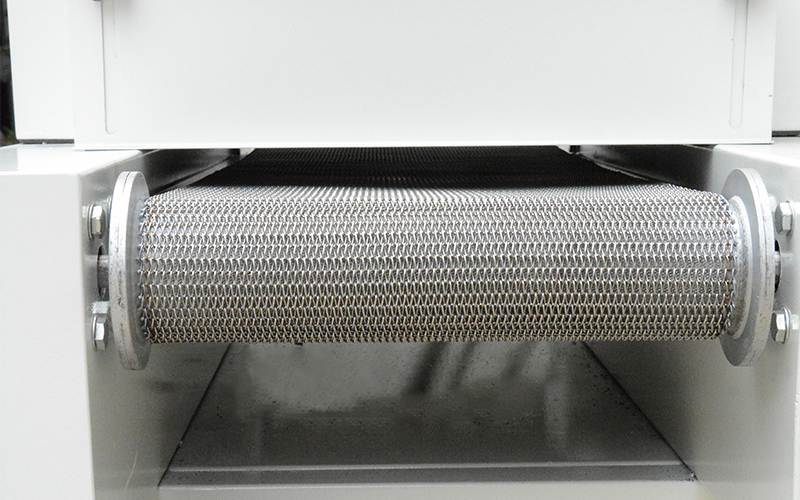

| Machine power | 5.5KW | Conveyor belt width | 350mm |

| Transfer speed | 0-10 m/min | Mesh belt material | Teflon |

| Light source configuration | 2KW*400mm380v*2pc | Main peak wavelength | 365nm (nanometer) |

| Power regulation | 20% - 100% power | Typical applications | Glue bonding, silk scree nprinting,etc. |

Product advantages

1. Instant drying, shortening process time

2. Wide application, reliable quality, safe use and convenient operation

3. Easy to operate, one button switch

4. The surface hardness of the cured product is improved and the color is beautiful.

5. Advanced cooling system, automatic control of heat dissipation time, ensuring that the workpiece is not affected by temperature and prolongs the service life of the lamp.

PRODUCT DETAILS

SIMPLE AND ELEGANT APPEARANCE

SAFE AND EASY TO OPERATE

USE REASONABLE AND RELIABLE

Stable and smooth performance

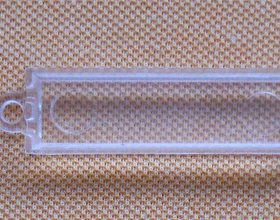

APPLICATIONS

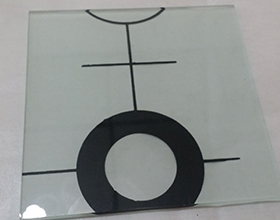

Transparent device bonding curing Display panel bonding curing

Glass bonding curing Silk screen process