You Might Also Like

-

High Quality Quartz UV Tungsten Lamp Tube UV Iodine Tungsten Lamp

-

8KW UV lamp frequency conversion power supply UV EPS

-

Laboratory proofing portable blue UV curing machine

-

Desktop standard spot printing UV curing machine

-

UV curing machine for OCA optical glue

-

Lithium battery uv curing machine

-

UV glue curing oven

-

UV curing machine for PU leather coating

-

UV curing machine for film

-

UV curing machine for screen printing

-

UV curing machine for Trademark

-

UV Curing Machine for Shoe Paint

Product Groups

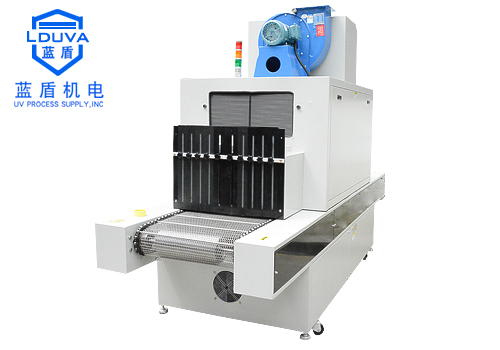

UV curing machine for screen printing

When screen printing is in multi-color registration, if the previous color dries too slowly, the ink of the previous color will easily stick to the screen during the second color registration.The ink will easily form mixed colors when printing the next color, so the drying speed of the first color should be Fast, the UV curing method has a fast curing speed. Generally, it will be dried in a few seconds under ultraviolet light, which will solve this problem.

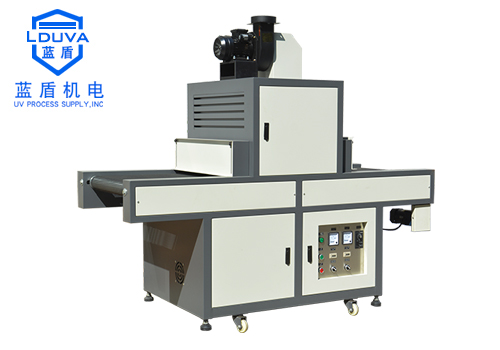

- Model:LDUVJ-2D-7.5KW

- Power:220VAC 50/60Hz

- Size:2000L*850W*1650H(mm)

- Wavelength:365nm

- Application range:screen printing

- Product Description

- Customer Question & Answer

UV Curing Machine for Shoe Paint

| Product name | UV curing machine for screen printing | Product number | LDUVJ-2D-7.5KW |

| Equipement size | 2000L X850W X1650H mm | Power supply | 380VAC 50Hz |

| Power | about 5.5kw | Belt width | 600mm |

| Transmission rate | 0--10m/min | Belt material | Teflon |

| Light source configuration | 2kw*2lamps,air-cooled lamp holder | Main crest length | 365nm |

| Power regulation | 20%--100% | Application range | Screen printing |

Product characteristics

The conveyor belt speed of this machine is adjustable,the UV lamp is equipment with two gears,the illumination area of the lamp

holder can be up, left and right can be adjusted, and seven sets of lamps are equipment with all-directional illumination curing, and the emergency stop button is equipment beside the inlet and outlet ports. The equipment has the charateristics of automatic detection and alarm system, convenient maintenance,golden durability and so on.

Application range

Product precautions

1. Before using this uv curing machine, please read the instructions in detail;

2. Do not look directly at the uv lamp and the light source for a long time, otherwise it will burn your eyes;

3. High voltage electricity danger;

4.When repairing and replacing parts, please turn off the main power supply, replace the uv lamp tube, and discharge the stored power of the capacitor;

5. Do not put your hands on the transmission part to avoid danger;

6. When testing the machine, please check whether the phase sequence of the fan is correct.

About UV machine product repair and maintenance

1. In order to prolong the service life of the uv equipment and ensure the normal operation of the equipment, the equipment should be checked before starting up, and the problems should be corrected in time.

2. Start running continuously for half an hour. Observe whether the indicators and indicators are normal, and whether there is any abnormal sound during operation. If abnormalities are found, check immediately.

3. Clean the panel at least once a month and check whether the screws of each part are loose.

4. Avoid touching the lamp tube with your hands to prevent sweat and oil from affecting the ultraviolet light transmission. If it is accidentally contaminated, it can be wiped clean with alcohol cotton.

5. The lamp tube and reflector should be wiped with alcohol once a month to keep them clean. If the surrounding environment is bad, increase the number of cleanings accordingly.

6. The exhaust fan should be cleaned every three months to clean the fan blades, the outside of the casing and the appearance of the motor.

7. Add lubricating oil to each rotating part of the fan, adjust the air valve drive mechanism, tighten each terminal, and check whether the air valve drive mechanism is flexible and reliable, and whether the wires are damaged.

8. If the small uv curing machine is not used for a long time, it is advisable to loosen the conveyor belt to make it in a free state.

9. After a period of use, the transmission chain will naturally extend and should be adjusted in time. During the use of the conveyor belt, due to temperature changes, there may be deviations, and should be adjusted in time.

10. Ensure the lubrication of the movable parts of the small uv curing machine. The active and passive rollers, bearings, chains and transmission wheels should be greased every six months; other parts and motors should be greased once a year.

11. After each use of the small uv curing machine, clean up the dirt and dust to ensure that the mesh belt runs freely.

12. Frequently check whether the plug of the small uv curing machine is in good contact with the socket. For example, when the price of the small uv curing machine is running normally, if the cable is found to be hot and hot, we must stop it.

13. The electrical wiring inside the machine must not be changed at will. In the event of a malfunction, check and repair in time, and non-professional maintenance personnel are not allowed to disassemble or replace it without authorization.

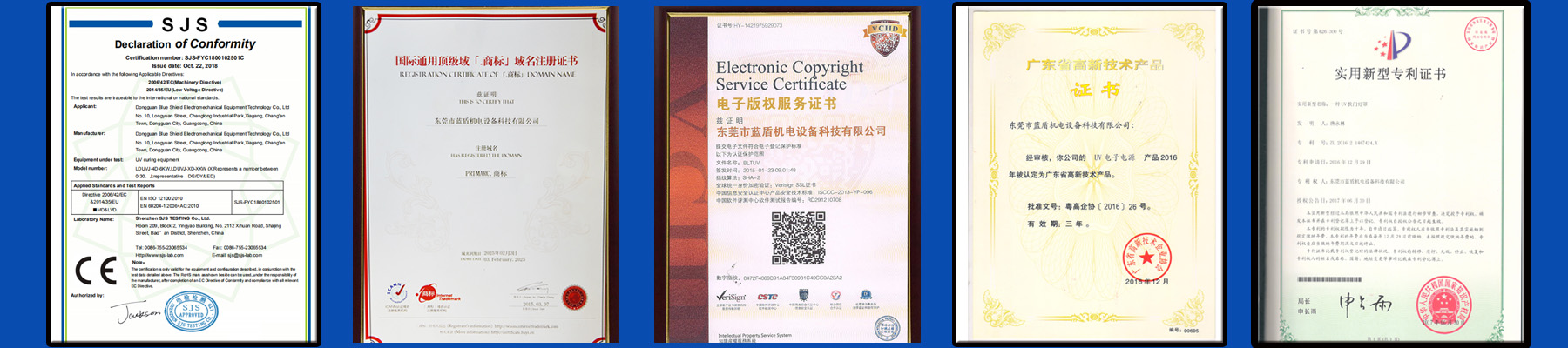

Why choose us?

1. Adopt stepless adjustable technology, with adjustable energy, one-key standby function, saving unnecessary energy consumption.

2. Passed the EU ce certification, won the title of Guangdong High-tech Enterprise, and each machine passed strict testing.

3. Recognized by more than 2000 customers, product applications in 60 different industries, 16 patented inventions, member of China Radiation Curing Association.

4. Lifetime free technical support, so that customers can enjoy good after-care services make our duty.

Certificate