You Might Also Like

Product Groups

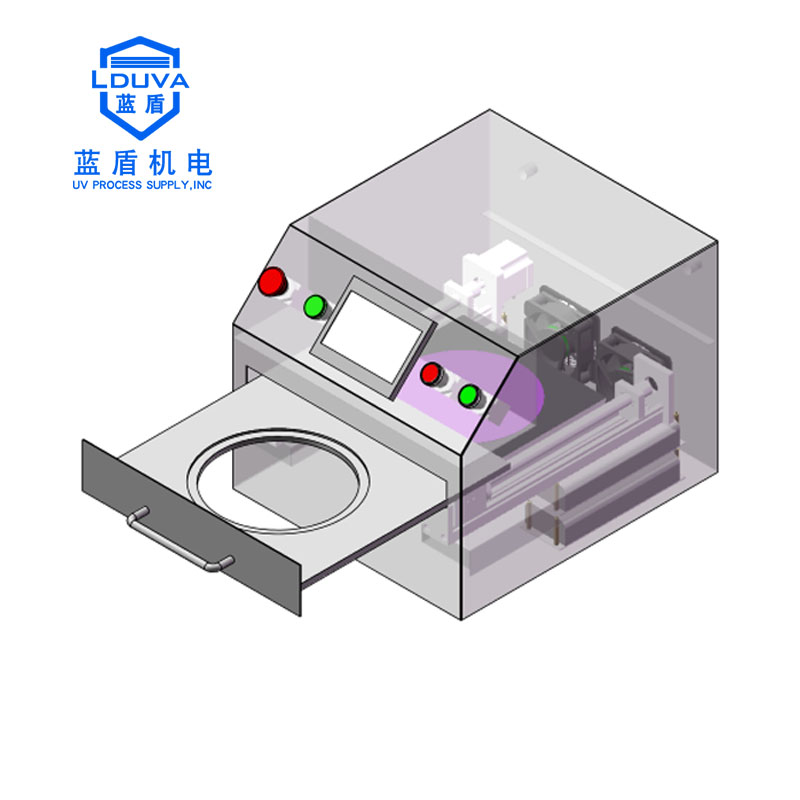

Uv-led film unglue machine | uv-led system

The latest development of UV LED unglue machine, luminous area of 300*300 mm uvled drawer type equipment.It has the characteristics of high ultraviolet irradiation intensity, good spot uniformity, simple operation, intelligent control system and high-power LED chip module, which guarantees the high efficiency of curing and the stability of quality, and can satisfy customers' perfect use in many fields.Reliability, stability and shorter curing time are important indicators.

Product characteristics: the curing time of adhesive generally takes 30 seconds, but the curing time will increase or decrease depending on the adhesive characteristics of the adhesive film, its suitability and the wavelength of the lamp tube.

- Model:A0c806-1

- Power:1200w

- Size:500mm(L)*500mm(W)*450mm(H)

- Wavelength:365nm or 395nm or 385nm or 405nm

- Application range:Suitable for wafer size: 6 ", 8 ", 12 "chip whole irradiation use

- Product Description

- Customer Question & Answer

Uv-led film unglue machine | uv-led system

The latest development of UV LED unglue machine, luminous area of 300*300 mm uvled drawer type equipment.It has the characteristics of high ultraviolet irradiation intensity, good spot uniformity, simple operation, intelligent control system and high-power LED chip module, which guarantees the high efficiency of curing and the stability of quality, and can satisfy customers' perfect use in many fields.Reliability, stability and shorter curing time are important indicators.

Product characteristics: the curing time of adhesive generally takes 30 seconds, but the curing time will increase or decrease depending on the adhesive characteristics of the adhesive film, its suitability and the wavelength of the lamp tube.

1. LED beads adopt imported light UVLED beads, with slow attenuation and long service life.

2. LED beads with short circuit, over current, over temperature and other protection functions.

3. The power of the light source can be set independently and displayed as a percentage, with the power adjustment accuracy up to 1%.(the starting power of curing equipment is 100% 8-10%)

4. Equipped with automatic, manual, ladder, pulse and other irradiation modes.

5. Equipped with perfect external I/O control interface to realize perfect connection with automation equipment;.

6. Touch operation panel, simple and intuitive operation.

7. Scientific heat dissipation structure design, to ensure the normal operating temperature of the equipment within the normal range, to ensure a constant output of light power

| NO. | Name | Parameter |

| 1 | Curing type | uv-led lamp |

| 2 | wavelength | 365nm or 395nm or 402nm |

| 3 | input power | 1200w |

| 4 | input voltage | 220v or 380v |

| 5 | working exposure distance | 5-20mm |

| 6 | type of cooling | forced air cooling |

| 7 | operating mode | PLC ( smart setting) |

| 8 | Module scalability | unable |

| 9 | work environment | Temperature: 25±5℃, Humidity:55% plus or minus 10% |