You Might Also Like

-

High Quality Quartz UV Tungsten Lamp Tube UV Iodine Tungsten Lamp

-

8KW UV lamp frequency conversion power supply UV EPS

-

Laboratory proofing portable blue UV curing machine

-

Desktop standard spot printing UV curing machine

-

UV curing machine for OCA optical glue

-

UV glue curing oven

-

Uv-led film unglue machine | uv-led system

-

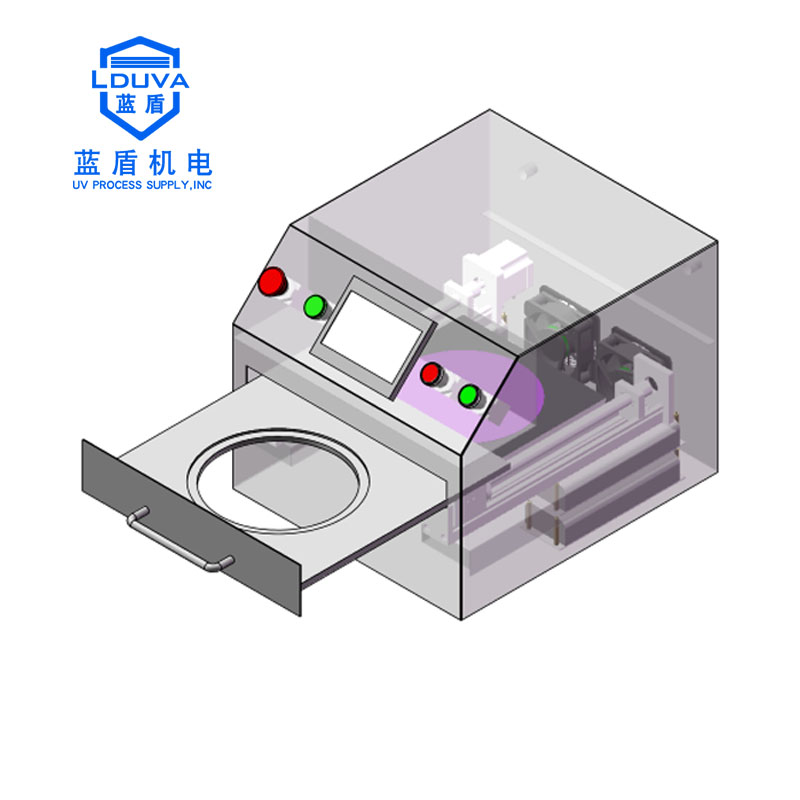

Box type uv curing machine| UV-curable adhesive monomer equipment

-

Desktop coating UV curing machine

-

Cosmetic bottle spray UV curing machine

-

Desktop 2KW LED UV curing machine for mouse wire bonding

-

Automatic drawer type UV glue curing machine

Product Groups

Low temperature UVLED curing system for quantum dot optical film

- Model:

- Power:

- Size:Customize the product according to the parameters of the customer's needs

- Wavelength:365nm

- Application range:The principle of UV curing is that ultraviolet rays are irradiated with special glue to cause polymerization of the glue to solidify. Different sizes of cured articles require different sizes of curing machines.Portable style, desktop case style, hanging style for industrial production, and large curing machine for large items.The speed adjustment drive keeps the speed of the conveyor belt uniform under different loads of UV machine.The UV machine is equipped with a high-intensity light source.

- Product Description

- Customer Question & Answer

COMMODITY PARAMETERS

| UV reference parameter | Optional | Native optional |

| Effective printing width: | Customized effective printing width according to client type | This machine is optional: 750mm |

| UV curing speed: | UV drying speed 9000-13000 sheets / H | This machine is optional: 9000-11000 sheets/H |

| UV LED wave band: | 365nm, 385nm, 395nm, 405nm | This machine is optional: 395nm |

| UV curing unit: | LED UV water-cooling, UV LED ultra low temperature | This machine is optional:Water-cooled led UV system |

| Color group UV lamp: | Select the number and power of LED UV lamps according to process requirements | This machine is optional:Depending on the model and process |

| Receiving UV light: | Select the number and power of LED UV lamps according to process requirements | This machine is optional:Depending on the model and process |

| LED UV light intensity: | 10W, 15W, 20W, 25W, 30W, 40W | This machine is optional:Depending on the model and process |

| LED UV energy: | 100mj-10000mj according to the production process | This machine is optional:To be determined |

▲Printable materials: all kinds of coated paper, gold and silver cardboard, aluminum foil paper, PET, BOPP, OPP, PE, PP, PVC, etc...

▲All LED UV curing system does not need to add mercury lamp, no need to change special LED UV ink, does not reduce the original UV printing speed, Blue Shield Electromechanical provides LED.UV system UV curing solution, UV LED system construction, according to different product requirements, Production process, tailor-made for you.

Product advantages

1. Low power consumption: The power consumption is only 30% of the traditional mercury lamp curing machine.

2. high energy low temperature: the use of German focused cold mirror, high permeability, high polymer, low temperature.

3. Customized convenience: The effective illumination area can be customized, and the corresponding LED UV can be customized according to the client type.

4. quality assurance: Japan and South Korea chips, all inorganic - packaging technology, German lenses and other effective quality assurance.

5. long life: LED-UV lamp life is more than 10 times that of traditional mercury lamps, and the service life is not affected by the number of switches.

6. Instant switch: The maximum power UV output can be achieved without preheating, and it can be restarted instantly after being turned off.

7. low temperature and high efficiency: cold light source UV equipment, temperature paper low energy, high light output, uniform illumination effect, improve production efficiency.

8. The LED UV curing unit for long-distance illumination uses two or three optical configurations such as the delivery of a sheetfed offset press, the spraying of automobiles and furniture, and the like.

9. In high-speed printing machines such as offset printing, gravure printing, flexo printing, and high-speed inkjet printing, we use the line focus light source method to achieve better results.

10. safety and environmental protection: no mercury, no heavy metal elements harmful substances, will not produce ozone, safety, environmental protection, energy saving, is a safer and more environmentally friendly alternative to traditional light source technology.

LED UV SYSTEM CONFIGURATION

This machine uses a stepless dimming system.

UV LED lamp intensity output 1% - 100% stepless dimming system output, multiple lights can be arbitrarily selected, each UV lamp does not interfere with each other, safe and stable.

Fully automatic computer-friendly human-machine dialogue interface, full Chinese display, fault alarm record filing and troubleshooting methods can be consulted at any time.

The mechanical equipment is designed to be reasonable and compact, and the failure rate is low. The main parts are imported with original products and independently developed products to ensure the safety and stability of the equipment.

The industrial series PLC module programming software is simple and easy to use. The LED UV and the printing machine realize the online control automatic synchronous operation, and the automatic conversion of the combined pressure and the weak light.

Electrical configuration: German Golden Bell Moeller, Japan and spring, Swiss ABB and other original products to ensure electrical safety and stability.

LED UV CURING UNIT

UV LED lamp: lamp or chip theoretical life 20000H-30000H

Energy-efficient: energy concentration, high power Suitable for curing deep products, focusing UV lampshade is small in size and easy to maintain.

Cooling method: The overall structure of water cooling is simple, and the internal closed circulating water circuit effectively reduces water leakage.

Low temperature design: The temperature of the workshop is within 25 °C, and the temperature of the printed product can reach no more than 42 °C after drying.

Color group UV LED curing unit

★ Phase-in design water-cooled LED UV lampshade, easy to install and maintain

★ The pedals need to be raised when some LED models are installed in some brand models.

★ Need to install LED UV lamp color seat between the UV lamp holder rail and water, electricity and other devices, uniform specifications can be exchanged

Overall UV LED curing unit

▲According to the model UV LED curing unit can be installed in the extended delivery section or the delivery slip

▲ Drawer or phase-in design water-cooled UV LED lampshade, easy to install and maintain.

▲The lower guide paper in the UV lamp irradiation area adopts European internal circulation water cooling and breeze jet structure, which is more effective in reducing temperature and preventing paper scratches.

LED UV SAFETY PERFORMANCE

1: Automatic leakage protection, in line with international safety standards. 2: Drawer shutter LED UV lamp cover, less light leakage and high efficiency. 3: Automatic detection and alarm protection of water flow and water temperature 4: The current has automatic protection such as overvoltage, overcurrent, overheating, open circuit and short circuit. 5: UV lamp cover, UV power supply temperature detection automatic protection 6: The lampshade cooling mode is cooled by water. 7: All fault alarm records are archived and can be viewed at any time. 8: The mechanical equipment design is reasonable and compact, and the failure rate is lower than that of similar products. 9: The whole machine has more than one hundred fault detection automatic protections to protect people and machines. |  |